Cedesa takes production to a new level with fast and furious new tube filler

For a packaging company to remain at the forefront of the industry it serves, it must build cutting-edge technology and operational efficiency into its production cycle.

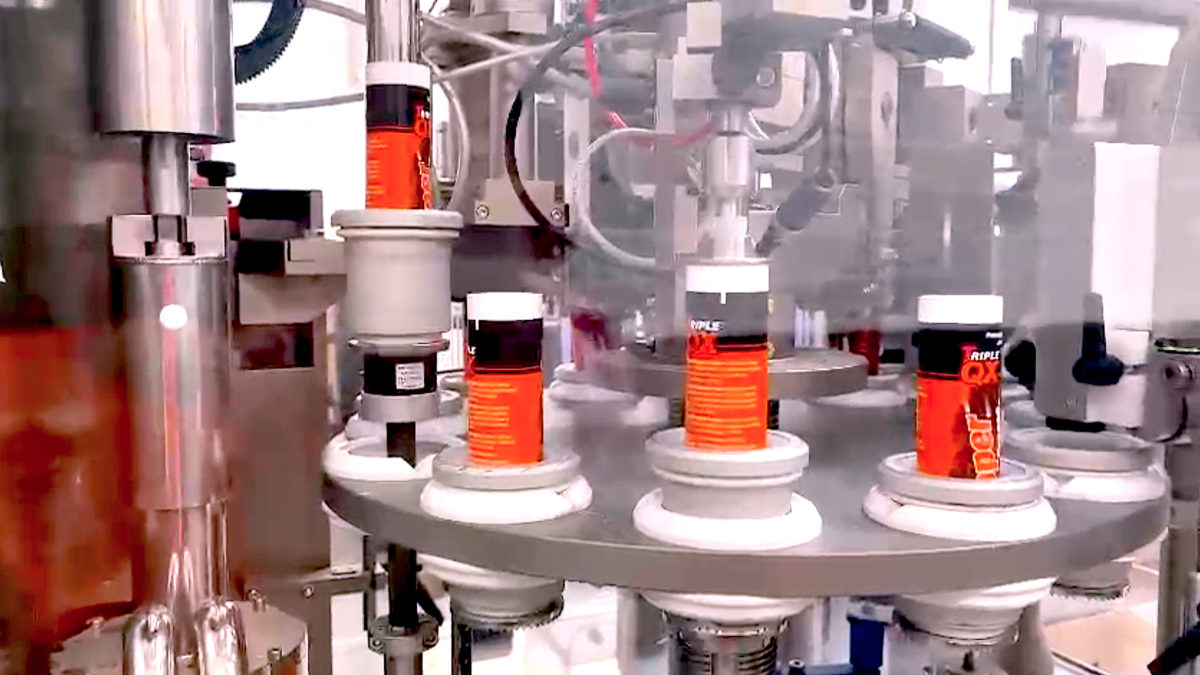

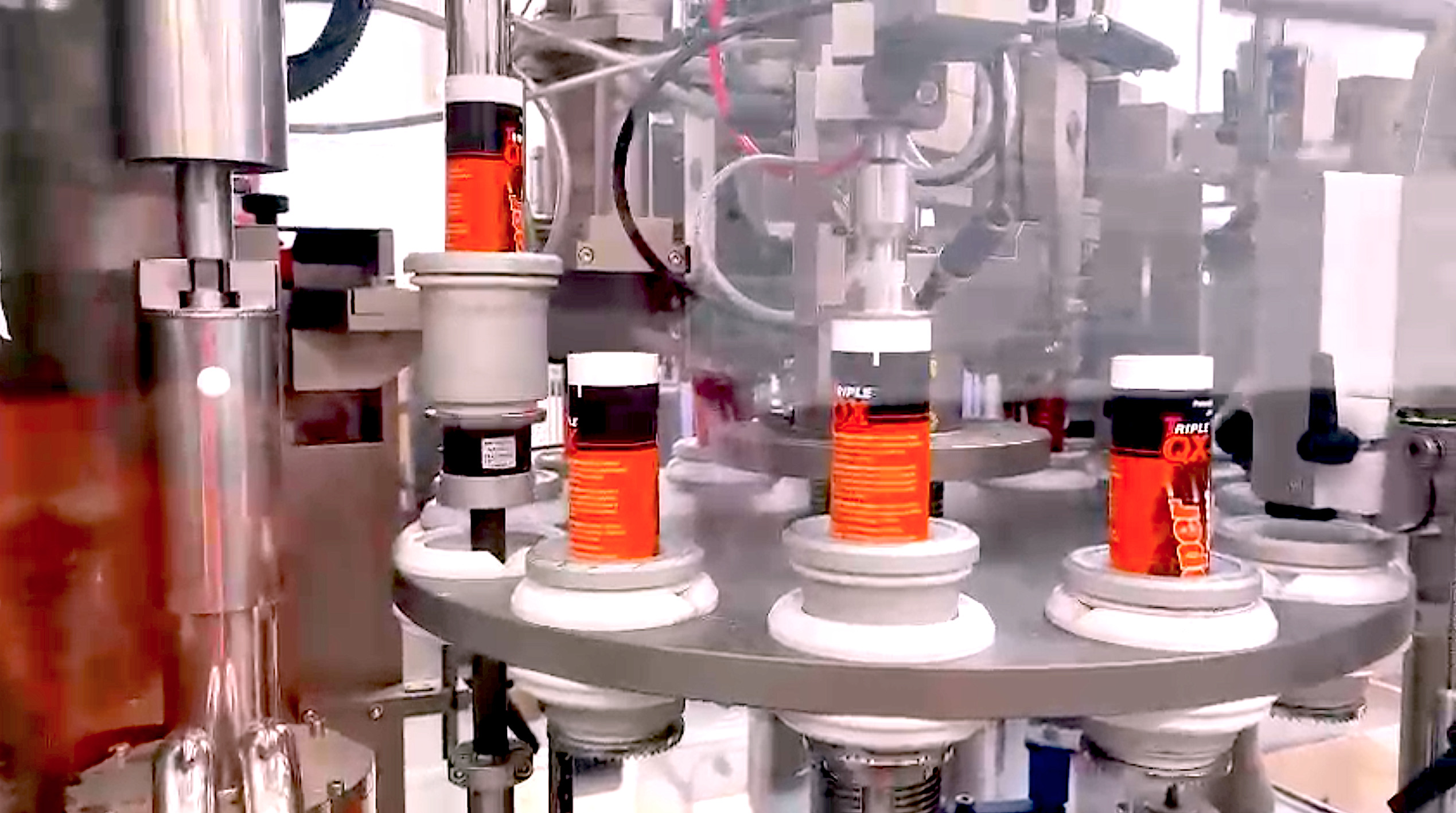

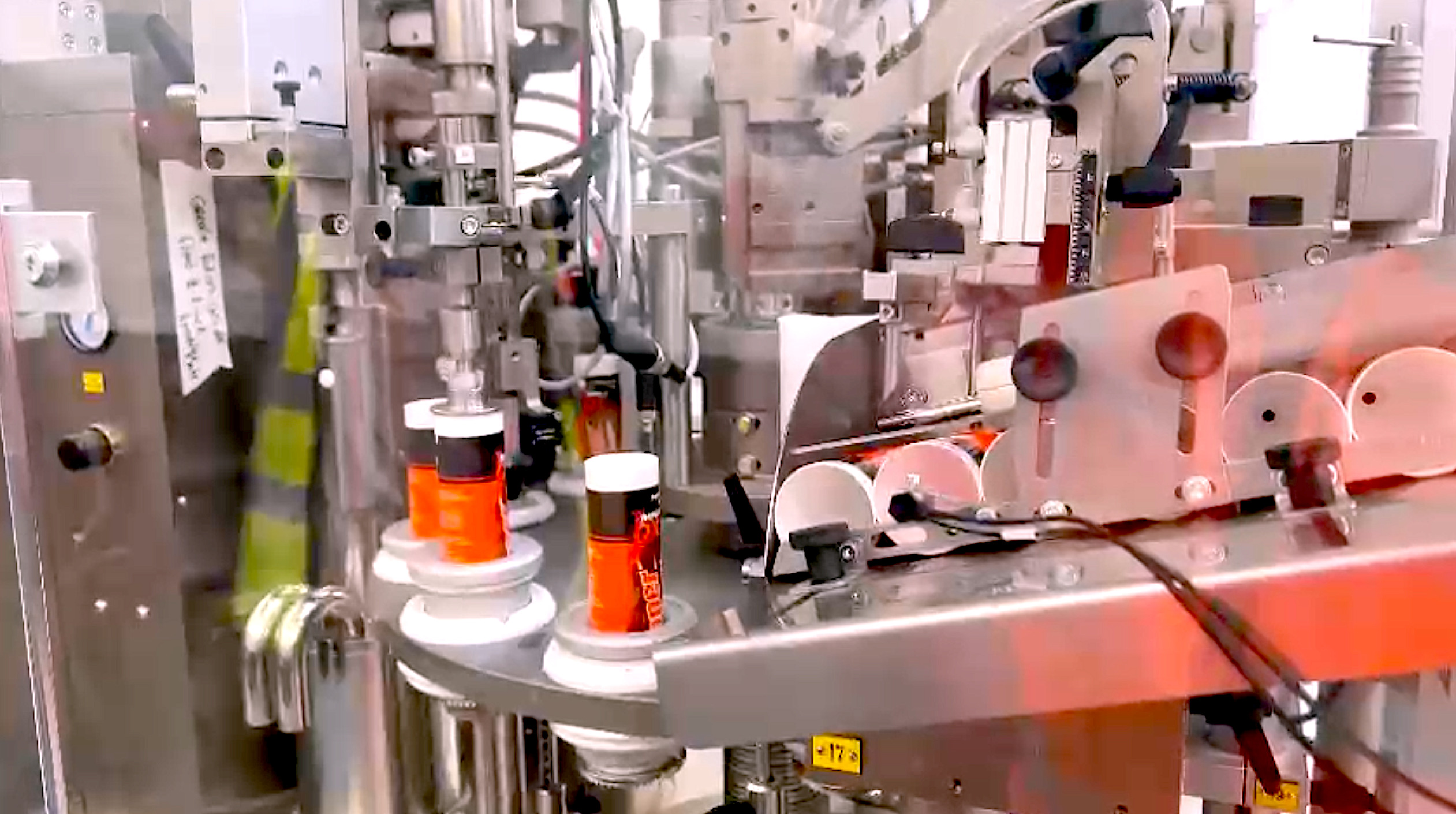

At Cedesa, we’ve taken productivity and quality to new levels by investing in a state-of-the-art aluminium and plastic tube filling machine; an incredible piece of equipment capable of delivering precise doses of fluids into packaging at high speed, with minimal waste.

In this article, we take a closer look at the potential impact of this significant investment.

A more efficient approach through advanced technology

Our business is built on our shared desire to define the industry standard. By investing in innovation, embracing state-of-the-art equipment like this aluminium and plastic tube filling machine, we’re putting our money where our mouth is.The technology we operate underscores our commitment to our clients, and to our team here at Cedesa. We’re a forward-thinking organisation and the production line is where we prove it; adapting to market demands and maintaining our competitive edge.

A new tube filling machine brings multiple efficiency enhancements to Cedesa's operations. It introduces automation, enabling us to transfer our team’s valuable expertise onto alternative operations without sacrificing productivity, while reducing the chance of human error. Streamlining our operations on the production line frees up resources that we can redirect towards client deadlines and the delivery of exceptional service.

Which brings us onto another of the key benefits of technological advance…

Expanding capacity without sacrificing quality

Cutting-edge equipment brings with it enhanced speed and efficiency, and a considerable increase in production output at Cedesa. But increased output counts for little without an in-step investment in the quality of our work.The advanced features of this piece of equipment mitigate the risk of defects and errors, ensuring a level of consistency and product integrity that is second to none. With the latest technology we can offer clients superior packaging solutions with precise fills, reduced leakage and enhanced product protection.

This commitment to quality positions the company as a reliable and trusted partner, ensuring a continuous, timely and increased supply of packaging solutions.

The decision to invest in a new aluminium and plastic tube filling machine marks a significant milestone for Cedesa, addressing the growing demands of clients and evolving market trends.

And we can’t talk about the future, without talking about...

Production line technology such as this introduces multiple operational benefits, including efficiencies that can be felt as much as on our profit margins.

Cedesa's investment in an aluminium and plastic tube filling machine represents a significant step forward for the company, solidifying our position as a leader in the packaging industry by increasing production capacity and the quality of our output. And by integrating advanced technology in our business process, we also open the door to unprecedented efficiency and a demonstrable commitment to sustainability.

As Cedesa looks ahead to continued innovation and adaptation, our clients can expect superior packaging solutions that meet their needs while building towards a greener future.

Delivering sustainability, at Cedesa and beyond

With its reduced energy consumption and highly efficient usage of material, our new tube filling machine underscores the eco-friendly strategy in place at Cedesa. Increased capacity and quality need not come at the expense of the planet, and we take the view that long-term investment must align with the environmental consciousness of both our clients and the audiences they serve.Production line technology such as this introduces multiple operational benefits, including efficiencies that can be felt as much as on our profit margins.

Cedesa's investment in an aluminium and plastic tube filling machine represents a significant step forward for the company, solidifying our position as a leader in the packaging industry by increasing production capacity and the quality of our output. And by integrating advanced technology in our business process, we also open the door to unprecedented efficiency and a demonstrable commitment to sustainability.

As Cedesa looks ahead to continued innovation and adaptation, our clients can expect superior packaging solutions that meet their needs while building towards a greener future.

More stories from around the world

Recent Posts

29 September 2023

It’s been almost three years since we put our teams at the centre of all we do and transitioned the business into an Employee Owned Trust […]

9 August 2023

For a packaging company to remain at the forefront of the industry it serves, it must build cutting-edge technology and operational efficiency into its production cycle. […]

11 July 2023

For more than three decades, Cedesa has been at the forefront of innovation and excellence in the manufacturing industry. So, how did we get here?